How do I choose the right fiber optic patch cable?

5 Steps to find the right fiber optic patch cable!

The right fiber optic patch cable is essential for a stable network. But how do you choose the right patch cable? What do you have to pay attention to? Which fiber optic patch cable is the best solution for your application?

In the next 5 steps you will read what you need to know to find the correct cable.

- When do I use fiber optic patch cables?

- Different types of fiber optic patch cables

- Quality attributes to a reliable network

- Construction of a fiber patch cable

- Different types of fibers and connectors used in patch cables

1. When do I use fiber optic patch cables?

Use fiber optic patch cables for connecting active equipment. Fiber optic patch cables are usually used for patching in 19” racks. In some cases, you will also find fiber optic patch cables in cable trays to cover greater distances.

Fiber optic patch cables can also be used for permanent cabling. Permanent cabling (also known as installation cabling) can be used both indoors in a building or outdoors, for example, in a Fiber to the Home network.

Fiber optic patch cables can also be used for permanent cabling. Permanent cabling (also known as installation cabling) can be used both indoors in a building or outdoors, for example, in a Fiber to the Home network.

2. Different types of fiber optic patch cables

See the different types of fiber optic patch cables below:

Types of fiber optic cables:

- Duplex patch cable

- Simplex patch cable

- Polarity twist™ patch cable

- Short boot patch cable

- Ruggedized patch cable

- Armoured patch cable

- MTP / MPO patch cable

- IP67 patch cable

Duplex patch cables - The most commonly used fiber optic patch cable - Receiving and sending data via two fibers

Duplex patch cables are the most commonly used fiber patch cables. Duplex patch cables are also called zip cords, patch cords or jumpers, consisting of two cables that are connected. With duplex patch cables two-way communication is possible for applications such as Internet and data communication because duplex patch cables use one fiber for sending and the other for receiving. Uniboot (HD), short boot, ruggedized and armoured patch cables are modern variants of duplex patch cables which offer certain advantages.

Simplex patch cables - Send and receive data over one fiber

Simplex patch cables consist of one cable with a connector on both sides. You can halve the use of cables/fibers with simplex patch cables. You have to use special fiber-optic modules that enable two-way communication over one fiber.

These cables are often applied in FTTH/telecom applications to minimize the number of fibers used. Simplex patch cables are only available in single mode.

These cables are often applied in FTTH/telecom applications to minimize the number of fibers used. Simplex patch cables are only available in single mode.

Polarity Twist™ patch cables, Save time and space

Equipment can be connected in different ways. Sometimes it’s necessary to change the polarity when installing or modifying cabling. Polarity Twist™ cables can change the polarity within seconds and save 60% on cabling volume compared to regular patch cables.

This makes Polarity Twist patch™ cables the best solution for high density applications. This reduction on cable volume makes cable management easier.

watch the video

This makes Polarity Twist patch™ cables the best solution for high density applications. This reduction on cable volume makes cable management easier.

Short boot patch cables - When there is little space for the connector

Short boot patch cables are ideal if there is limited space for the connector. E.g. when housing is compact or when there is little space between the panel and the door of a 19" rack. Short boot patch cables are similar to duplex patch cables, but are distinguished by a shorter boot/tule.

Ruggedized patch cables - Better mechanical protection

Ruggedized patch cables can be used for lengths of 10 meters or more. Standard patch cables are intended for short distances within a 19" cabinet. Ruggedized patch cables have an extra jacket for better mechanical protection. They are also called Flatoval fiber cables because of the shape of the extra jacket.

Armoured patch cables - The best mechanical protection

If your patch cables are exposed to extreme conditions, choose armoured patch cables. These are patch cables with a metal protective layer that makes the cables even more robust and thus better protected. These types of patch cables are often used in industrial and offshore applications.

IP67 patch cables – for outdoor use, water and dust resistant

For outdoor use, you can use patch cables with an IP67 connector to get water and dust resistance. These cables are often used to connect antennas in a Mobile transmission tower with ground wiring to provide access to wireless applications such as Wi-Fi or mobile internet.

MTP|MPO patch cables – excellent for high speed connections

If you want to connect at higher speeds (40G and up), the MTP/MPO patch cable is an excellent choice. Both the cable and connector contain 12 or more fibers and by combining the bandwidth of these fibers, high speeds are achieved. These cables are often used in situations where the need for bandwidth is high and the distances relatively short, usually up to 100 meters. Examples are data centers and server rooms.

3. Quality attributes to a reliable network

How do you determine the quality of a fiber patch cable? Based on the appearance of a cable you can’t determine the quality. How do you determine the quality of a fiber patch cable? There are a number of points that you should take into account for determining the quality.

Grades

The International Electrotechnical Commission (IEC) has established different degrees of quality. Grade A to Grade C. Grade A assures the best quality fibers and connectors. We recommend Grade A for professional applications where reliability comes first.

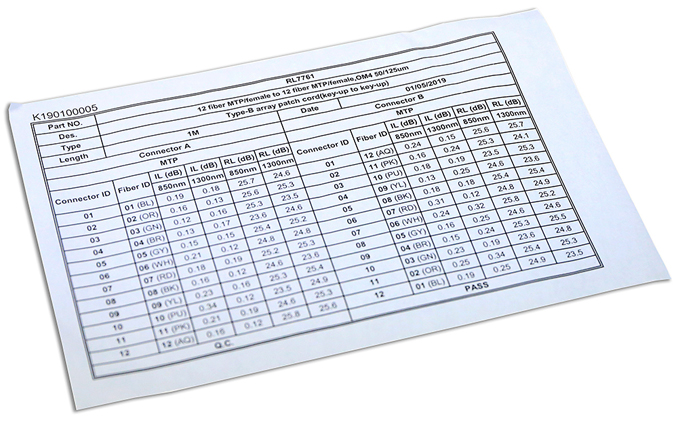

Test report

In addition, we advise you to opt for fiber optic cables that are equipped with an individual test report. This means that each fiber in the cable has been tested for the attenuation of light.This attenuation has a direct influence on the speed and reliability of your network. By opting for fiber optic patch cables with an individual test report, you are assured of a cable that has been tested and you are aware of the attenuation values in your network.

Quality control in the production process

However, fiber type and an individual test report do not tell the whole story. The production process and its quality control are of great importance. An incorrect polished connector can reduce the optical performance of your connector within a short period of time after installation. This is not visible in the test report because it is measured immediately after production. It can also occur with Grade A parts in case of errors in the production process.If you choose a reputable brand, the chance of errors in your network is minimal.

ACT is a renowned brand and has built a reputation over the years by delivering consistent quality. At ACT we are proud of this and we will do everything we can to continue to deliver high consistent quality. With ACT cabling you are assured of a reliable network.

4. Construction of a fiber patch cable

A fiber patch cable is assembled of the following elements:

- The fiber

- Primary and secondary coating: strengthens the fiber and makes it suitable for installation.

- Kevlar*: the fiber is protected against tensile stress by the Kevlar/aramid around the secondary coating.

- The outer jacket (also called jacket): strengthens the construction and protects the cable against external influences.

5. Different types of fibers used in patch cables

Fiber optic patch cables are available with different types of fibers.

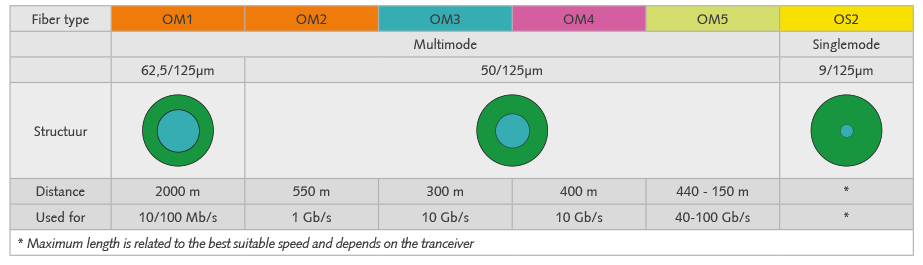

Multimode fiber for short distances

Multimode fibers are used for short distances and have a LED or VCSEL as light source. These fibers are limited in length and speed. Several generations of multi-mode fibers are available, from OM1 to OM5. Which variant you can use best depends on the application and whether you are going to expand an existing network. Find more information in the table below.Single mode fiber for long distances

Single mode fibers are used for longer distances and have almost infinite bandwidth. The light source of a single-mode fiber is a laser, which makes it more powerful and accurate, but also more expensive than a LED or VCSEL. Lately, however, the price difference has been steadily decreasing, as a result of which singlemode is increasingly being used for short distances as well.

Different types of fibers:

Deutsch (Deutschland)

Deutsch (Deutschland)

Español (España, Alfabetización Internacional)

Español (España, Alfabetización Internacional)

Français (France)

Français (France)

Magyar (Magyarország)

Magyar (Magyarország)

Nederlands (Nederland)

Nederlands (Nederland)